Posted on October, 2, 2024 at 10:45 am

Regenerative practices have gained popularity within the UK over recent years. Aside from the environmental and biodiversity benefits, many of the practices are also thought to improve profitability. Within this series of two articles, we will look at UK wheat data, collected through the AHDB benchmarking tool, Farmbench. We will explore the impact a selection of practices often included in regenerative systems have on costs, profitability and production.

There are 241 harvest 2023 winter wheat enterprises recorded in this analysis, including milling and feed varieties.

Each farm was asked which of fifteen practices they carried out (shown below) and split into the following groups: ‘High’ (9-14 practices), ‘Medium’ (5-8 practices), and ‘Low’ (0-4 practices).

As may be expected, certain practices were more popular within each group. Establishing cover crops, applying organic manures and growing a long and broad rotation were each taken up by more than 63% of the enterprises. For the ‘low’ group (0-4 practices), these practices made up a larger percentage of the practices they used. The ‘high’ group (9-14 practices) used more practices relating to reduced tillage and lowering inorganic fertiliser use than the other groups.

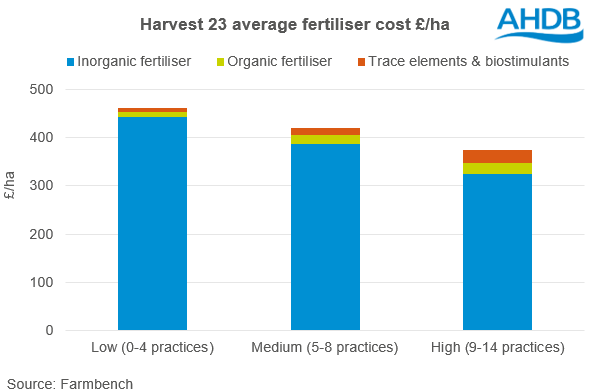

As would be expected, the focus the ‘high’ group had on using less synthetic fertiliser, resulted in lower inorganic fertiliser costs than the ‘medium’ (5-8 practices) and ‘low’ groups, as shown in Figure 1. The average wheat crop in the ‘high’ group tended to spend £29/ha more on organic manure and trace elements, including biostimulants, but made larger savings by cutting their inorganic fertiliser use by 48kg/ha of nitrogen. This resulted in an inorganic fertiliser saving of £117/ha in comparison to the ‘low’ group, and an overall fertiliser saving of £88/ha. This reduction in fertiliser use also likely contributes to the slightly lower overhead costs such as labour and fuel in the ‘high’ group. However, other practices the group used could also contribute to this cost saving.

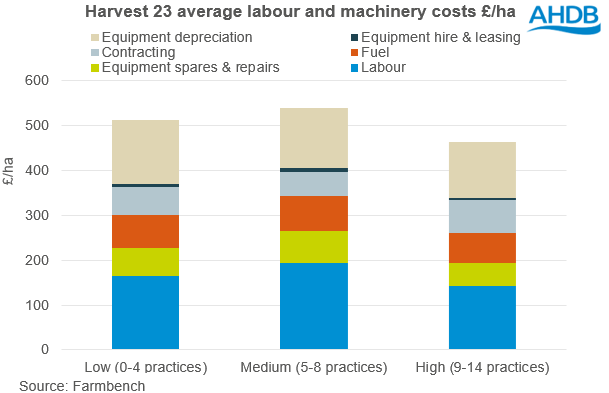

Another key difference in the systems was the use of low or no till cultivation. The ‘high’ group used these practices more than the other groups. They spent the least on labour and machinery costs overall, saving up to £76/ha in comparison to the ‘medium’ group, shown in Figure 2. Aside from the clear cost savings by reducing cultivations, such as to fuel spend, the ‘high’ group made savings in their business structure. The ‘high’ group are keeping less kit on farm, reducing their depreciation costs, and employing more contractors. Contracting was the only machinery and labour cost which the ‘high’ group spent more than the ‘medium’ and ‘low’. This may partially be due to less machinery needed within low tillage systems but could also relate to a tendency to hire in specialised equipment from other businesses.

The average wheat enterprise within the ‘high’ group had the lowest total cost of production at £1312/ha, benefitting from the key cost savings explored in this article. The ‘medium’ and ‘low’ groups had a similar cost of production, £1451/ha and £1452/ha respectively, meaning that the ‘high’ group had saved 9.6% of costs in comparison to the other groups. Look out for the next article where we will explore how these groups differ in yields, income and as such, profitability.

Source: AHDB